How Drone Inspections Are Transforming Lift Shaft Safety in Hong Kong

Drones are changing how lift shafts are inspected in Hong Kong, making inspections safer, faster, and more efficient.

Safety: Drones eliminate the need for inspectors to enter confined, hazardous spaces, reducing risks like falls and toxic gas exposure.

Speed: Inspections are completed up to 90% faster by avoiding time-consuming setups like scaffolding.

Cost: Costs are reduced by as much as 70%, cutting down on labour and equipment expenses.

Data Quality: High-resolution visuals and 3D mapping provide precise, reliable information for maintenance and compliance with Hong Kong's regulations.

With these advantages, drones address challenges in Hong Kong's dense urban environment, such as narrow shafts, limited access, and weather disruptions. This shift is supported by the Housing Authority's adoption of drones in its inspection standards, ensuring compliance while improving efficiency and safety.

How Drones Operate in Lift Shaft Inspections

Drone Features for Inspections

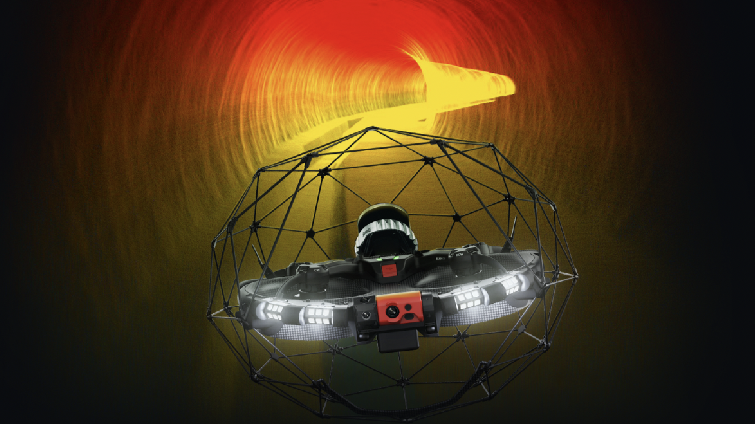

Modern inspection drones are built to handle the unique demands of lift shaft inspections. Their collision-tolerant designs let them navigate tight spaces, even in older buildings, without being thrown off course by minor bumps. Protective frames add an extra layer of durability, ensuring they can handle these challenging environments.

Equipped with high-resolution cameras and real-time HD video capabilities, these drones provide immediate, detailed visuals of critical components like cables, pulleys, and guide rails. This allows inspectors to spot wear and structural issues that might be missed during manual checks. The image quality is precise enough to meet CAD standards, making it easier to document findings accurately.

Another standout feature is integrated LiDAR technology, which creates precise 3D maps of the shaft. This ensures accurate measurements and helps maintain compliance with Hong Kong's regulatory standards. The data collected feeds into detailed reports, making the inspection process not only thorough but also efficient and compliant.

Working in Confined and Dangerous Spaces

Drones are specifically designed to tackle the challenges of confined and hazardous spaces. Advanced navigation systems keep them stable even in areas where traditional GPS signals fail, a common issue in Hong Kong's dense and complex urban settings. This reliability significantly reduces the risks associated with manual inspections.

Operators control these drones remotely using first-person view systems that stream real-time video. This setup allows precise navigation and detailed inspections from the ground, even when the drone is operating several floors above. The ability to hover steadily in one spot makes it possible to closely examine specific components from multiple angles, ensuring nothing is overlooked.

To further enhance safety and efficiency, drones come with built-in protocols like automatic return-to-home features. These safeguards kick in during communication failures or technical glitches, minimising downtime and keeping the inspection process on track despite the challenges posed by Hong Kong's unique environments.

Benefits of Drone Lift Shaft Inspections

Improved Safety for Inspection Teams

Using drones for lift shaft inspections removes the need for human entry into hazardous, confined spaces. This reduces risks like falls, exposure to toxic gases, and contact with raw sewage - dangers that are often part of manual inspections [3]. Models such as the Elios 3, equipped with collision-tolerant designs, allow inspectors to perform assessments remotely through high-resolution visuals, thermal imaging, and 3D mapping [1]. In Hong Kong, where older buildings often present unexpected risks within lift shafts, AI-powered drones add an extra layer of safety. These drones autonomously detect structural issues, leaks, and maintenance needs, ensuring inspections are both thorough and safe [2].

Faster Operations with Minimal Downtime

Speed is another major advantage of drone inspections. Traditional methods often involve time-consuming steps like setting up scaffolding, safety gear, and coordinating teams. In contrast, drones can be deployed almost instantly, completing inspections up to 90% faster. This efficiency minimises disruptions, allowing lift services to resume quickly - a critical benefit in Hong Kong's densely populated areas. Additionally, in emergencies, drones can perform inspections immediately without the delays of lengthy preparation, ensuring safety concerns are addressed promptly.

Cost Efficiency and Long-Term Savings

Drone inspections offer significant cost reductions. According to Drone Solutions Asia, inspection costs can be cut by up to 70% compared to traditional methods. This is achieved by eliminating the need for scaffolding, access towers, and large teams of specialised workers. Over time, the savings add up, particularly for buildings requiring regular inspections under Hong Kong's strict regulations. Beyond immediate cost savings, drones support better maintenance planning by improving defect monitoring and asset management. This leads to more predictable maintenance budgets and reduces unexpected expenses, complementing the faster and safer inspection processes.

Enhanced Data Quality and Efficient Record Keeping

Drones provide high-resolution visuals and precise measurements, often surpassing what human inspectors can achieve in confined lift shafts. With integrated LiDAR technology, drones create detailed 3D maps that meet Hong Kong's regulatory standards. This high-quality data improves defect tracking and enables predictive maintenance, ensuring issues are addressed before they escalate. Additionally, digital records simplify compliance reporting, providing clear evidence for Housing Authority requirements and CAD standards. Real-time data capture also speeds up decision-making and maintenance scheduling, making the entire process more efficient and reliable.

Hong Kong Regulations and Standards

Civil Aviation Department (CAD) Requirements

https://www.cad.gov.hk/

CAD Website

In Hong Kong, drone operations, including those used for lift shaft inspections, are governed by the Civil Aviation Department (CAD) under the Small Unmanned Aircraft Order (Cap. 448A). These regulations establish the framework for ensuring safe and compliant drone use throughout the region.

Housing Authority and Industry Standards

In addition to CAD oversight, the Hong Kong Housing Authority (HA) has incorporated drone technology into its smart estate management programme for public housing estates, starting in 2023 [4]. From early 2025, consultancy contracts for lift modernisation projects will require the use of drones for inspections [4]. The HA is actively assessing how these inspections enhance maintenance efficiency and lower accident risks, using these insights to refine their approach [4].

To address privacy concerns, the HA collaborates closely with the Office of the Privacy Commissioner for Personal Data. Measures such as automatic face blurring and strict data retention policies are enforced to safeguard personal information during drone operations [4].

This Drone Measures Elevator Shafts Better Than Humans!

Drone vs Manual Inspection Methods

When comparing drone-based and traditional manual inspection methods, the advantages of drones become increasingly clear. In Hong Kong's lift shaft inspections, this shift in approach is transforming how property managers, engineering consultants, and facility operators handle their inspection needs. By understanding the key differences between these methods, stakeholders can make smarter decisions about their strategies.

Manual inspections involve physical entry into lift shafts, requiring specialised equipment and posing several challenges. On the other hand, drones offer a modern alternative that addresses many of these limitations.

Safety concerns stand out as the most significant difference. Manual inspections put workers at risk by exposing them to confined spaces and potential hazards. Drones eliminate this risk entirely, as they can operate in hazardous areas without requiring human presence.

Efficiency is another area where drones excel. Manual inspections often involve lengthy preparations, coordination, and downtime. In contrast, drones can be deployed quickly, minimising disruptions to lift operations - a crucial consideration in Hong Kong's densely packed urban environment.

Data collection capabilities also set the two methods apart. Traditional inspections rely on visual checks and handwritten notes, which can be subjective and limited. Drones, however, capture high-resolution videos and images, along with precise measurements, creating detailed records that are both comprehensive and compliant. Here's a quick comparison:

Comparison Table of Inspection Methods

Manual inspections are not only more expensive, due to labour and equipment costs, but they also result in longer downtime and less detailed documentation. Drones, on the other hand, provide faster, more cost-effective assessments, offering insights that help with maintenance planning and meeting Hong Kong's strict regulatory requirements.

Scheduling flexibility is another advantage of drones. Manual inspections often require long shutdowns and coordination with multiple contractors, causing significant inconvenience. Drones can be scheduled with minimal notice, completing inspections during shorter maintenance periods and reducing disruptions for building occupants.

These distinctions illustrate why more property developers, facility managers, and engineering consultants in Hong Kong are adopting drone-based inspections. With their ability to enhance safety, reduce costs, and deliver superior data, drones are becoming the go-to solution for modern lift shaft assessments.

Drone Solutions Asia has been making waves in Hong Kong by showing how drone inspections can improve safety, reduce costs, and increase efficiency - particularly in the city's lift shafts and other confined spaces.

Confined Space Inspection Projects

In Hong Kong's dense urban landscape, confined space inspections present unique challenges. Drone Solutions Asia has tackled these head-on with their use of the Elios and AspiraCopter systems. These compact drones are purpose-built to navigate tight and difficult-to-reach areas, making them a perfect fit for the city's infrastructure.

Traditionally, inspections of confined spaces like tunnels, lift shafts, and culverts required extensive scaffolding, specialised safety equipment, and large teams of personnel. By contrast, these drones capture real-time high-resolution video and LiDAR mapping data, providing detailed visuals and precise measurements - all without the need for human entry.

For underground spaces, drones eliminate the need for costly setups and logistical challenges. The AspiraCopter, in particular, stands out for its ability to manoeuvre through spaces that were previously inaccessible or too expensive to inspect. Its compact design ensures it can reach even the most restricted areas, making it a game-changer for confined space inspections.

These successful projects highlight the potential of drone technology to revolutionise inspection processes in urban environments.

Client Results and Outcomes

The benefits of Drone Solutions Asia’s technology are reflected in their clients' results, with improvements seen across several key performance areas.

One of the standout advantages is enhanced safety. By removing the need for human entry into hazardous spaces, the risk of workplace accidents is effectively eliminated. This not only protects workers but also reduces insurance liabilities and compliance costs for property owners.

Another major benefit is the quality of data. The drones provide high-definition video footage and precise LiDAR measurements, creating a permanent record that clients can use for maintenance planning, defect tracking, and even predictive maintenance. This comprehensive documentation supports future inspections and long-term asset management.

Additionally, the ability to schedule inspections on short notice means clients can respond quickly to safety concerns or meet regulatory requirements without delays. This flexibility ensures that inspections are not only thorough but also timely.

These case studies demonstrate how drone technology is reshaping the inspection process in Hong Kong. It’s not just about replacing traditional methods - it’s about delivering better results. With improved safety, lower costs, and higher-quality data, Drone Solutions Asia is setting a new standard for urban infrastructure inspections in the region.

Conclusion: The Future of Lift Shaft Safety in Hong Kong

Drone technology is reshaping how lift shafts are inspected in Hong Kong, offering a safer and more efficient alternative to traditional methods. In a city known for its densely packed urban landscape, this innovation is a game-changer.

With inspections now up to 90% faster and costs slashed by as much as 70%, drones eliminate the need for manual entry into tight, hazardous spaces. This not only reduces risks for workers but also streamlines the entire process.

What’s more, these advancements fit seamlessly within Hong Kong’s stringent regulatory framework. By meeting standards set by the CAD and the Housing Authority, drones provide a scaffold-free inspection method that ticks all the compliance boxes.

The use of real-time high-resolution video and LiDAR mapping adds another layer of precision. These tools improve documentation, aid in maintenance planning, ensure regulatory compliance, and support better long-term management of lift systems.

FAQs

How do drones make lift shaft inspections safer and more efficient?

Drones are transforming lift shaft inspections by prioritising safety and efficiency. By eliminating the need for human inspectors to enter confined and hazardous spaces, drones significantly reduce the risks of falls, injuries, and exposure to dangerous conditions. At the same time, they deliver precise, reliable data from a safe distance.

When compared to traditional inspection methods, drones bring several advantages to the table. They can effortlessly navigate tight, hard-to-reach areas, capture high-resolution images, and detect potential issues with impressive accuracy. Plus, they do all this while minimising operational disruptions and cutting costs. This makes drones a practical and effective solution for addressing the challenges posed by Hong Kong's densely packed urban infrastructure.

What technologies do drones use to meet Hong Kong's safety and regulatory standards during inspections?

In Hong Kong, drones play a crucial role in lift shaft inspections by employing a mix of cutting-edge technologies to meet strict local regulations, including CAD standards. These technologies include:

Geofencing systems: These ensure drones stay out of restricted zones, offering an additional layer of operational safety.

Altitude and distance controls: These features help maintain safe operational boundaries, preventing accidents or regulatory breaches.

Real-time tracking: This allows for continuous monitoring of flight paths, ensuring transparency and accountability during inspections.

Remote pilot licensing: Certifies that operators are trained and qualified to handle drones safely and in compliance with regulations.

By combining these tools, drones not only improve safety but also reduce risks and ensure inspections align with Hong Kong’s stringent regulatory standards.

How do drones help reduce maintenance and operational costs for lift shaft inspections in Hong Kong?

Drones are transforming the way lift shaft inspections are carried out in Hong Kong, offering a more efficient and cost-effective approach for property managers. By removing the need for costly scaffolding and cutting down on manual labour, drones can reduce inspection expenses by up to 70%. On top of that, they speed up the entire process, helping to minimise downtime and avoid disruptions to building operations.

Safety is another big win here. Drones significantly lower the risks faced by human inspectors, as they can operate in confined or hazardous spaces without putting anyone in harm's way. Equipped with advanced imaging and sensor technology, drones also deliver highly accurate inspection results. This makes them an ideal tool for ensuring lift shaft safety in Hong Kong’s tightly packed urban landscape, where efficiency and precision are key.